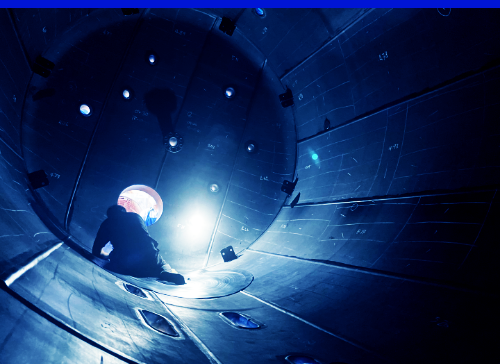

Rubber Lining is an application method used to protect multiple types of systems by lining corrosion and abrasion-resistant rubber upon the surface or inside of pipes and tanks.

Lining is done by hand by our experienced staff for a durable finished product, so having application accuracy by qualified liners and crews are a must.

The equipment to be lined, working conditions and environment are different for each customer. Therefore, selecting the most suitable material is a crucial procedure that we provide to cater to their specifications.

Flake Lining is anti-corrosive coating systems for severe exposures.

Flake compound is made from thermosetting liquid resin mixed with glass flakes in microns thick and applied in a thickness of 0.5~3.0mm.

Glass flakes as barrier fillers make the coating much more durable and prevent permeability of corrosive substances, as the layers of laminated glass flakes (50~100 layers in 1mm thickness) form a highly impermeable structure.